Heavy Duty Metal Lined Slurry Pump for Mining & Tailings | Kenda Pump

100% compatible with Warman AH series slurry pumps

SPECIFICATIONS:

-Discharge diameters 1” to 18” (25mm to 450mm)

-Capacity: up to 5400 m3/h

-Head: up to 68m

-Speed: 200-3800r/min

-Materials: Cast iron, Ductile iron, High chrome alloy, Natural rubber etc

Kenda KH(R) Series Slurry Pumps Key Features | High Wear-resistant Industrial Transfer Solutions

Engineered for the Toughest Abrasive Challenges

The Kenda Metal Lined Slurry Pump is a premier heavy-duty, horizontal centrifugal pump designed specifically to handle high-density, abrasive, and coarse slurries in demanding industrial environments. Built with a robust double-casing structure, this pump ensures maximum safety and operational reliability under high-pressure conditions.

Superior Wear Resistance with High-Chrome Alloy

At the heart of our metal-lined series is the interchangeable A05 High-Chrome Alloy (27% Cr) liners and impellers. Unlike standard pumps, our metallurgy is vacuum-cast to ensure zero porosity, providing exceptional hardness (HRC 60+) and resistance against particle impingement. This significantly extends the mean time between maintenance (MTBM), reducing your total cost of ownership (TCO).

Advanced Hydraulic Design & Versatility

Our engineering team has optimized the impeller vanes to provide the highest hydraulic efficiency without compromising wear life. The pump features:

Replaceable Metal Liners: Precision-fit liners are bolted (not glued) for easy replacement and maintenance.

Flexible Sealing Options: Choose from Expeller Seals (centrifugal) for waterless operation, Packing Seals, or customized Mechanical Seals for zero-leakage requirements.

Multi-Stage Capability: Designed to allow multiple units to be installed in series for high-head, long-distance tailings disposal.

Built for Global Standards

Kenda pumps are engineered to be dimensionally interchangeable with leading international brands, making them the ideal choice for plant upgrades or as high-performance replacements. Whether you are managing mineral processing (copper, gold, iron ore), coal washing, or power plant ash removal, our metal-lined pumps deliver consistent flow rates and superior suction performance in the harshest pH environments.

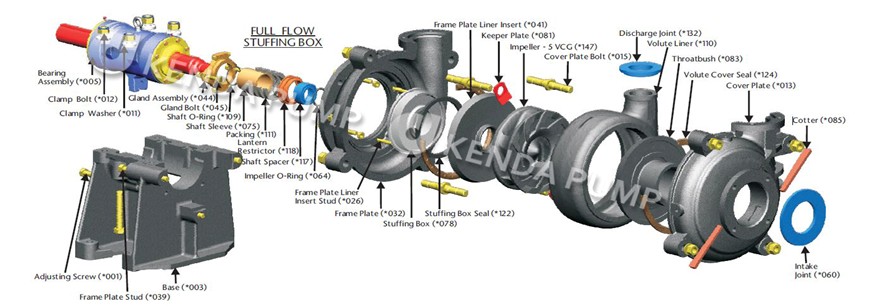

Kenda KH Slurry Pump Structure

Features

Pump- Cantilever, horizontal centrifugal slurry pump.

Wet parts-Impellers, volutes, liners are made of high chrome alloy or rubber or polyurethane, anti-abrasive, wear resistant and corrosion resistance.

Bearing assembly- Tubular structure bearing assembly, design of high capacity bearing. Grease lubrication, oil lubrication helps to adapt to different operating conditions.

Shaft seal- Sealed by packing or centrifugal.

Pump exit position- Based on 450 interval, rotating eight different angles of installation.

Kenda KH Series Slurry Pump Technical Specifications Chart

Model | Max. Motor Power (kW) | Material | Clear Water Performance | Impel. Dia. (mm) | |||||

Liner | Impeller | Capacity Q (m³/h) | Head H(m) | Pump Speed n(r/min) | Max. Eff. η% | NPSH (m) | |||

KH-1B | 15 | M | M | 12.6-28.8 | 6-68 | 1200-3800 | 40 | 2-4 | 152 |

KHR-1B | 15 | RU | RU | 10.8-25.2 | 7-52 | 1400-3400 | 35 | 2-4 | 152 |

KHH-1C | 30 | M | M | 16.2-34.2 | 25-92 | 1400-2200 | 20 | 2-5.5 | 330 |

KH-1.5B | 15 | M | M | 32.4-72 | 6-58 | 1200-3200 | 45 | 3.5-8 | 184 |

KHR-1.5B | 15 | RU | RU | 25.2-54 | 5.5-41 | 1000-2600 | 50 | 2.5-5 | 178 |

KH-2C | 30 | M | M | 39.6-86.4 | 12-64 | 1300-2700 | 55 | 4-6 | 214 |

KHR-2C | 30 | RU | RU | 36-75.6 | 13-46 | 1300-2300 | 60 | 2-4 | 213 |

KHH-2D | 60 | M | M | 68.4-136.8 | 25-87 | 850-1400 | 47 | 3-7.5 | 457 |

KH-3C | 30 | M | M | 86.4-198 | 9-52 | 1000-2200 | 71 | 4-6 | 245 |

KH-3D | 60 | M | M | 86.4-198 | 9-52 | 1000-2200 | 71 | 4-6 | 245 |

KHR-3C | 30 | RU | RU | 79.2-180 | 5-34.5 | 800-1800 | 59 | 3-5 | 245 |

KHR-3D | 60 | RU | RU | 79.2-180 | 5-34.5 | 800-1800 | 59 | 3-5 | 245 |

KHH-3E | 120 | M | M | 126-252 | 12-97 | 600-1400 | 50 | 2-5 | 508 |

KH-4D | 60 | M | M | 162-360 | 12-56 | 800-1550 | 65 | 5-8 | 365 |

KH-4E | 120 | M | M | 162-360 | 12-56 | 800-1550 | 65 | 5-8 | 365 |

KHR-4D | 60 | RU | RU | 144-324 | 12-45 | 800-1350 | 65 | 3-5 | 365 |

KHR-4E | 120 | RU | RU | 144-324 | 12-45 | 800-1350 | 65 | 3-5 | 365 |

KHH-4F | 260 | M | M | 324-720 | 30-118 | 600-1000 | 64 | 3-8 | 711 |

KHH-6S | 560 | M | M | 468-1008 | 20-94 | 500-1000 | 65 | 4-12 | 711 |

KH-6E | 120 | M | M | 360-828 | 10-61 | 500-1140 | 72 | 2-9 | 510 |

KH-6R | 300 | M | M | 360-828 | 10-61 | 500-1140 | 72 | 2-9 | 510 |

KHR-6E | 120 | RU | RU | 32-720 | 7-49 | 400-1000 | 65 | 5-10 | 510 |

KHR-6R | 300 | RU | RU | 32-720 | 7-49 | 400-1000 | 65 | 5-10 | 510 |

KH-8ST | 560 | M | M | 612-1368 | 11-61 | 400-850 | 71 | 4-10 | 686 |

KHR-8ST | 560 | RU | RU | 540-1188 | 12-50 | 400-750 | 75 | 4-12 | 686 |

KM-8E | 120 | M | M | 540-1440 | 14-60 | 600-1000 | 73 | 4-10 | 549 |

KM-8R | 300 | M | M | 540-1440 | 14-60 | 600-1000 | 73 | 4-10 | 549 |

KH-10ST | 560 | M | M | 936-1980 | 7-68 | 330-800 | 82 | 6 | 762 |

KHR-10ST | 560 | RU | RU | 720-1620 | 7-45 | 300-650 | 80 | 2.5-7.5 | 762 |

KH-12ST | 560 | M | M | 1260-2772 | 13-63 | 300-600 | 77 | 3-10 | 965 |

KHR-12ST | 560 | RU | RU | 1152-2520 | 13-44 | 300-500 | 79 | 3-8 | 965 |

KH-14TU | 1200 | M | M | 1368-3060 | 11-63 | 250-550 | 79 | 4-10 | 1067 |

KH-16TU | 1200 | M | M | 2160-5054 | 8-66 | 200-500 | 80 | 4.5-9 | 1245 |

KH-18TU | 1200 | M | M | 2520-5400 | 13-57 | 200-400 | 85 | 5-10 | 1370 |

Kenda KH Series Slurry Pump Material Options Chart

Slurry Pump Parts | Material | Specification | HRC | Application | Material Code |

Volute Liner, Impeller | Hard Metal | 23%-30% chrome white iron | ≥56 | Used for higher wear conditions with PH between 5 to 12 | A05 |

14%-18% chrome white iron | ≥59 | Used for higher wear conditions | A07 | ||

27%-29% chrome white iron | 43 | Used for lower PH conditions especially for FGD. Its also can be used for low-sour conditions and desulfuration with PH no less than 4. | A49 | ||

Rubber | Standard Impeller Rubber | R08 | |||

Standard Liner Rubber | R26 | ||||

Natural rubber (soft) | R33 | ||||

Natural rubber | R55 | ||||

Hypalon | S31 | ||||

PU | Polyurethane | U01 | |||

Expeller, Expeller Ring | Metal | 23%-30% chrome white iron | ≥56 | Used for higher wear conditions with PH between 5 to 12 | A05 |

Grey iron | G01 | ||||

Stuffing Box | Metal | 23%-30% chrome white iron | ≥56 | Used for higher wear conditions with PH between 5 to 12 | A05 |

Grey iron | G01 | ||||

Frame Plate, Cover Plate, Bearing House, Base | Metal | Grey iron | G01 | ||

Ductile iron | D21 | ||||

Shaft | Metal | Carbon Steel | E05 | ||

Shaft Sleeve, Lantern Ring, Resctrictor Neck Ring, Gland Bolt | Stainless Steel | 4Cr13 | C21 | ||

304 SS | C22 | ||||

316 SS | C23 | ||||

Joint Rings, Seals | Rubber | Butyl rubber | S21 | ||

EPDM rubber | S01 | ||||

Nitrile | S10 | ||||

Hypalon | S31 | ||||

Neoprene | S44, S42 | ||||

Viton | S50 |

Metal Lined Slurry Pump Applications:

• Mining | • Mineral processing | • Coal prep | • Cyclone feeds |

• Tunnel | • Chemical slurries | • Tailings | • Mill grinding |

• Ash handing | • Paper and Pulp | • Waste sludge | • Coarse sand |

• Lime mud | • Phosphoric acid | • Dredging | • Construction |

• Alumina Industry | • Power Plant | • Potash Fertilizer Plant | • Other industries |

Looking for durable metal lined slurry pumps? Kenda's A05 high-chrome alloy pumps offer superior abrasion resistance for mining and mineral processing. 100% Interchangeable with Warman AH。Request a quick quote today!

Frequently Asked Questions (FAQ)

Q1: How do I choose between Metal Lined and Rubber Lined Slurry Pumps?

A: The choice primarily depends on the particle size and shape of your slurry.

Metal Lining (High-Chrome Alloy): Best for handling large, coarse, or sharp particles and high-impact conditions (e.g., primary mining or gravel). It offers superior hardness (HRC 60+).

Rubber Lining: Ideal for fine particles (typically <5mm) and highly corrosive or acidic environments (pH 2-13). If your application involves heavy mining tailings or crushed ore with sharp edges, a Metal Lined Slurry Pump is usually the more durable choice.

Q2: Why is my pump impeller wearing out faster than expected?

A: Accelerated wear is often caused by three main factors:

Operating Away from BEP: If the pump operates too far from its Best Efficiency Point, internal turbulence increases, causing localized erosion.

Material Mismatch: The slurry's hardness might exceed the limits of the impeller alloy.

Cavitation: Insufficient suction pressure creates vapor bubbles that implode on the metal surface, pitting the impeller. Tip: Regularly adjust the impeller clearance to maintain high efficiency and reduce backflow erosion.

Q3: Are Kenda Metal Liners interchangeable with other major brands?

A: Yes. Kenda slurry pumps are engineered to be dimensionally interchangeable with international industry standards. Our wet-end parts—such as impellers, volute liners, and throat bushes—fit seamlessly into existing pump casings of similar designs. This allows you to upgrade to Kenda’s high-performance A05 wear-resistant parts without replacing your entire pump system, significantly reducing maintenance costs.

Q4: How can I extend the service life of a High-Chrome Alloy Slurry Pump?

A: Proactive maintenance is key to longevity:

Impeller Adjustment: Periodically adjust the gap between the impeller and the throatbush to compensate for wear and maintain hydraulic performance.

Seal Maintenance: Ensure the expeller seal is properly lubricated or that the gland packing has the correct flow of cooling water to prevent slurry from entering the shaft sleeve.

Avoid Dry Running: Never run the pump without fluid, as this causes rapid heat buildup and can damage the mechanical seals or internal liners.

Q5: What is the maximum solid size a Kenda Metal Lined Pump can handle?

A: The maximum allowable particle size depends on the specific pump model and its discharge diameter. Generally, our metal-lined pumps are designed with wide internal passages to handle solids up to 50% to 80% of the discharge pipe diameter, depending on the particle concentration and shape. For specific spherical clearance data, please consult our engineering team with your slurry analysis.

Case Studies

Case Study 1: Improving Efficiency in a Coal Preparation Plant (Australia)

Industry: Coal Washing & Preparation

Challenge: An Australian coal plant struggled with high energy consumption and leaking shaft seals in their heavy-media circuit. They needed a reliable, high-efficiency solution that could integrate into their existing pipeline without costly modifications.

Our Solution: Kenda provided dimensionally interchangeable metal lined pumps with optimized Expeller Seals (Centrifugal Seals). This allowed the plant to operate without seal water, preventing slurry dilution.

Results:

Perfect Fit: 100% compatibility with existing piping, reducing installation time by 70%.

Energy Efficiency: The optimized hydraulic design led to a 12% reduction in power consumption.

Zero Leakage: The expeller seal eliminated the need for gland water, saving thousands of gallons of water daily.

Case Study 2: High-Head Tailings Disposal for an Iron Ore Project

Industry: Iron Ore Mining

Challenge: The project required transporting high-density iron ore tailings over a distance of 3km with a vertical lift of 60 meters. A single-stage pump could not handle the required head pressure.

Our Solution: Kenda engineers designed a multi-stage pump system using three 6/4D-MAH Metal Lined Slurry Pumps installed in series. The double-casing design of our pumps ensured they could safely withstand the high internal pressures of a multi-stage setup.

Results:

Steady Performance: The system maintained a consistent flow rate of 350 m³/h at the required pressure.

Durability: Despite the high-pressure environment, the metal liners showed minimal signs of wear after 4,000 hours of continuous operation.

Safety: The robust outer casing provided an extra layer of protection for onsite workers.

Categories

Contact Us

- +86-15031155425

- sales@kendapump.com

- +86-15031155425