KV Series Vertical Cantilever Slurry Pump (Sump Pump) | No Submerged Bearings | Kenda Pump

100% compatible with Warman SP/SPR series slurry pumps

SPECIFICATIONS:

-Capacity: up to 1260 m3/h

-Head: up to 40m

-Speed: 350-2200r/min

-Materials: Cast iron, Ductile iron, High chrome alloy, Natural rubber etc

Kenda KV Series Vertical Cantilever Slurry Pump are centrifugal slurry pumps, designed for handling abrasive and corrosive slurries whilst submerged in sumps or pit. The pump has no shaft seal, easy to maintenance and cost less. Hard metal and rubber parts are optional for different applications and interchangeable. Suit for most applications where slurry pumps are needed.

Technical Advantages

Cantilever Design : Explain that the bearings are above the fluid level. This means zero leakage and lower maintenance costs compared to submersible pumps with mechanical seals.

No Shaft Seal Required: Emphasize that it can run dry without damage. This is a huge selling point for varying sump levels.

Interchangeable Wet Ends: Highlight that users can switch between High Chrome (A05) for abrasion and Natural Rubber (R55) for corrosion.

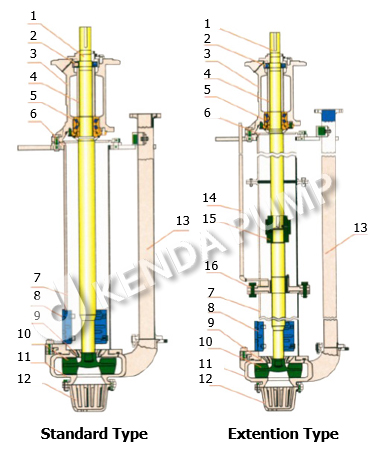

Structure

Metal Lined Vertical Slurry Pump | Rubber Lined Vertical Slurry Pump | ||||

No. | Part Name | Materials | No. | Part Name | Materials |

1 | Shaft | 4140 High Tensile Steel | 1 | Shaft | 4140 High Tensile Steel |

2 | Bearing | SKF/ Timken (standard) | 2 | Bearing | SKF/ Timken (standard) |

3 | Bearing Housing | HT250 | 3 | Bearing Housing | HT250 |

4 | Bearing Spacer | 420 Stainless Steel | 4 | Bearing Spacer | 420 Stainless Steel |

5 | Bearing | SKF/ Timken (standard) | 5 | Bearing | SKF/ Timken (standard) |

6 | Shim | 20# Stainless Steel | 6 | Shim | 20# Stainless Steel |

7 | Column | 20# Stainless Steel | 7 | Column | 20# Stainless Steel |

8 | Strainer | QT500-7 | 8 | Strainer | Natural Rubber |

9 | Frame Plate Liner Insert | 27% Chrome Alloy | 9 | Frame Plate Liner Insert | Natural Rubber |

10 | Impeller | 27% Chrome Alloy | 10 | Impeller | Natural Rubber |

11 | Pump Casing | 27% Chrome Alloy | 11 | Pump Casing | Natural Rubber |

12 | Lower Strainer | QT500-7 | 12 | Lower Strainer | Natural Rubber |

13 | Discharge Pipe | 20# Stainless Steel | 13 | Discharge Pipe | 20# Stainless Steel |

14 | Flushing Pipe | Q235 Carbon Steel | 14 | Flushing Pipe | Q235 Carbon Steel |

15 | Coupling Part | 45# Steel | 15 | Coupling Part | 45# Steel |

16 | Middle Supporting Part | 20# Stainless Steel | 16 | Middle Supporting Part | 20# Stainless Steel |

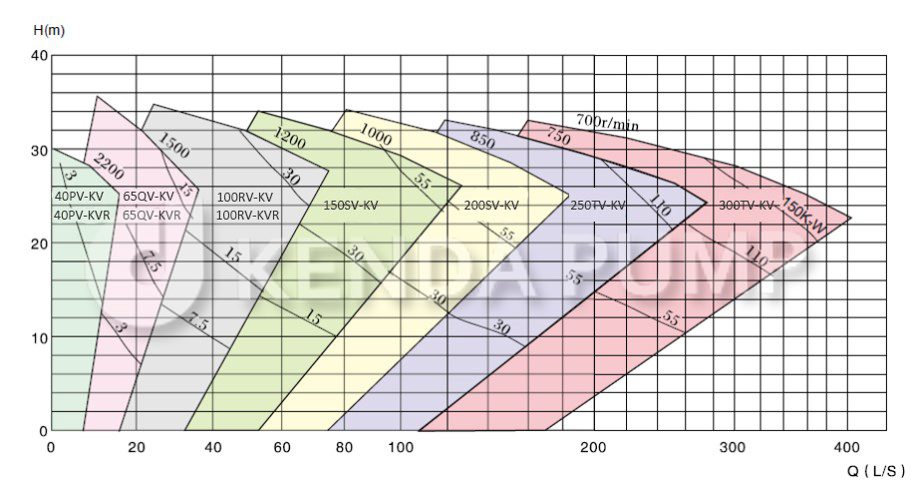

Quick Selection Chart

Technical Specifications Chart

Model | Max. Motor Power (kW) | Material | Capacity Q(m³/h) | Head H(m) | Pump Speed (r/min) | Max. Eff. η % | No. of Vanes | Impel. Dia. (mm) | |

Liner | Impeller | ||||||||

40PV-KV | 15 | M | M | 19.44-43.2 | 4.5-28.5 | 1000-2200 | 40 | 5 | 188 |

40PV-KVR | 15 | RU | RU | 17.28-39.6 | 4-26 | 1000-2200 | 40 | 5 | 188 |

65QV-KV | 30 | M | M | 24.3-111 | 5-29.5 | 700-1500 | 50 | 5 | 280 |

65QV-KVR | 30 | RU | RU | 22.5-105 | 5.5-30.5 | 700-1500 | 51 | 5 | 280 |

100RV-KV | 75 | M | M | 54-289 | 5-35 | 500-1200 | 56 | 5 | 370 |

100RV-KVR | 75 | RU | RU | 64.8-285 | 7.5-36 | 600-1200 | 62 | 5 | 370 |

150SV-KV | 110 | M | M | 108-479.16 | 8.5-40 | 500-1000 | 52 | 5 | 450 |

200SV-KV | 110 | M | M | 189-891 | 6.5-37 | 400-850 | 64 | 5 | 520 |

250TV-KV | 200 | M | M | 261-1089 | 7.5-33.5 | 400-750 | 60 | 5 | 575 |

300TV-KV | 200 | M | M | 288-1267 | 6.5-33 | 350-700 | 50 | 5 | 610 |

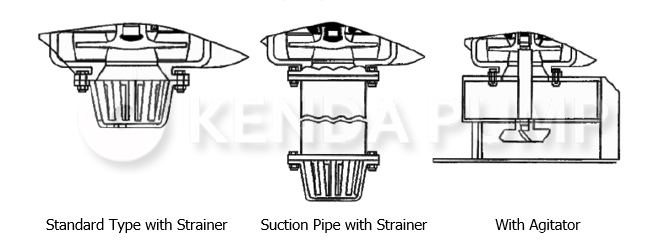

Pump type diagram

Industrial Applications

Mining & Mineral Processing: Handling spillage from sumps, feeding hydrocyclones.

Power Plants: Ash handling and sump cleanup in desulfurization plants (FGD).

Chemical Processing: Transferring corrosive acids or alkalis where mechanical seals fail.

Installation and Maintenance Guide

Suction Extension: Explain that suction pipes can be extended for deeper sumps (up to 2 meters).

Impeller Adjustment: Briefly explain how to adjust the impeller clearance externally to maintain efficiency over time.

V-Belt Drive: Mention the flexibility of adjusting pump speed (RPM) using different pulley ratios.

FAQ

Q: Can the KV vertical pump run dry?

A: Yes, thanks to the cantilever design without shaft seals, the pump can run dry indefinitely without damage.

Q: What is the maximum submerged depth?

A: Standard insertion depth is 900mm to 1200mm, but customized extension shafts are available for deeper sumps.

Q: Difference between KV and KVR series?

A: KV uses metal liners for coarse solids; KVR uses rubber liners for fine, corrosive slurries.

Disclaimer

KENDA is not affiliated with or in any way connected to Warman® of Weir Minerals Group. All names, numbers, symbols, and descriptions are for reference only and do not suggest that any listed pumps or parts are products of Warman Pumps; Kenda slurry pump are only compatible with Warman® slurry pump. This document is the property of Kenda Pump and may not be reproduced or disclosed to any third party without prior written authorization.

Categories

Contact Us

- +86-15031155425

- sales@kendapump.com

- +86-15031155425