KLS Series Single-stage Double-suction Split-case Pump | KLS80-210 to KLS350-510 | Kenda Pump

SPECIFICATIONS:

Discharge Diameter: DN 80 ~ 800 mm

Flow Rate Range: 83.5 ~ 9810 m³/h

Head Range: 13.8 ~ 160 m

Operating Temperature: +1℃ ~ +80℃

Inlet Pressure: Up to 0.6 MPa (depending on material)

Looking for a high-efficiency Single-stage Double-suction Split-case Pump? The KLS Series features a robust split-case design, ideal for heavy-duty water transport. View specs & get a quote today!

Kenda KLS series single-stage double-suction split-case pump is a new generation of products developed by integrating advanced international double-suction pump technology with high-efficiency hydraulic models. Designed for municipal water supply, HVAC cooling systems, and industrial irrigation. Its axially split casing allows for easy access to internal components without disturbing piping—perfect for reducing downtime in critical applications.

Technical Advantages

Easy Maintenance: Featuring a horizontally split-case design, it allows for internal inspections and parts replacement without dismantling the inlet/outlet pipelines or the motor.

Smooth Operation: The symmetrical double-suction impeller design theoretically balances axial forces automatically, resulting in low vibration and noise during operation.

Flexible Configuration: Supports both horizontal and vertical installation (for small models); sealing options include packing seals or mechanical seals; the direction of rotation can be customized upon request.

Long Service Life: The shaft is completely sealed and does not come into contact with the medium, effectively preventing corrosion and significantly extending the operating life.

Product Classification

Based on the medium being transported, the KLS series offers three professional configurations:

Standard Type: Designed for clean water and pure liquids with physical and chemical properties similar to clean water.

Wear-resistant Type: Specially engineered for silty rivers and water with high sand content (solid particles ≤ 80mg/L), offering higher efficiency and enhanced wear resistance.

Corrosion-resistant Type: Utilizes specialized corrosion-resistant materials and mechanical seals, suitable for transporting various chemically corrosive liquids.

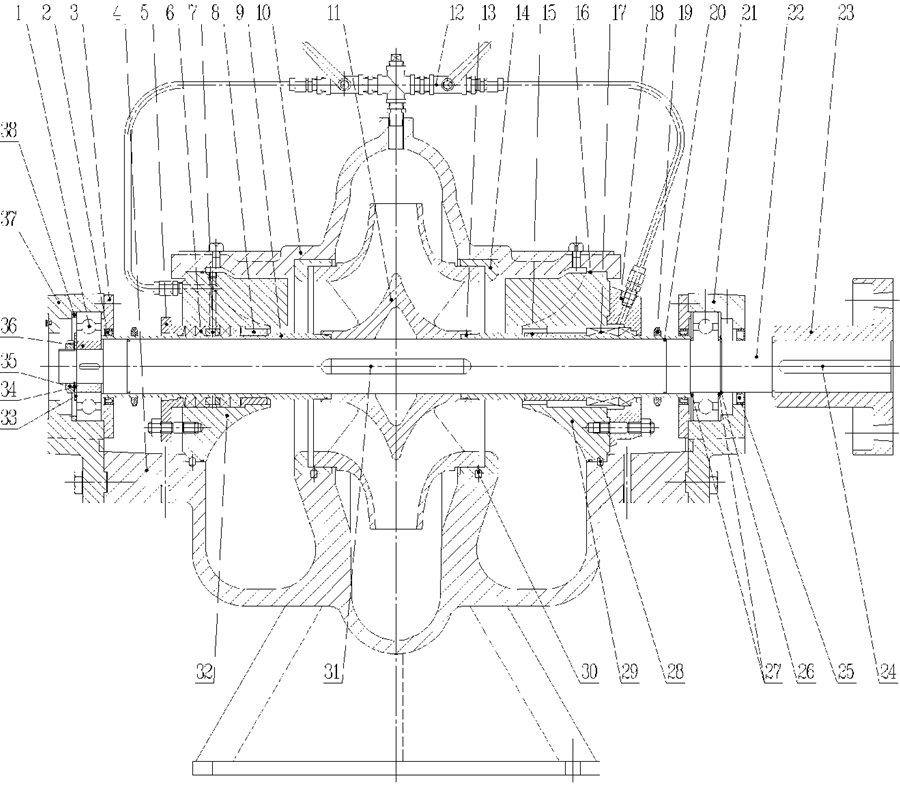

Structure

1 | Bearing | 11 | Impeller | 21 | Drive-end Bearing House | 31 | Type B Flat Key |

2 | Skeleton Oil Seal | 12 | Flushing Pipe Assembly | 22 | Shaft | 32 | Seal Body |

3 | Bearing End Cover | 13 | O-ring | 23 | Pump Coupling | 33 | Retaining Ring / Stop Ring |

4 | Pump Casing | 14 | Casing Seal Ring | 24 | Type C Flat Key | 34 | Lock Nut Washer |

5 | Packing Gland | 15 | Mechanical Seal Bushing | 25 | Skeleton Oil Seal | 35 | Lock Nut |

6 | Packing | 16 | O-ring | 26 | Circlip for Shaft | 36 | Bearing Inner Sleeve |

7 | Lantern Ring / Packing Ring | 17 | Mechanical Seal | 27 | Bearing Press Ring | 37 | Non-drive-end Bearing House |

8 | Packing Sleeve | 18 | Mechanical Seal Gland | 28 | Cylindrical Pin | 38 | Bearing Locating Ring |

9 | Shaft Sleeve | 19 | Water Slinger / Deflector | 29 | Seal Body | ||

10 | Pump Cover | 20 | O-ring | 30 | Cylindrical Pin |

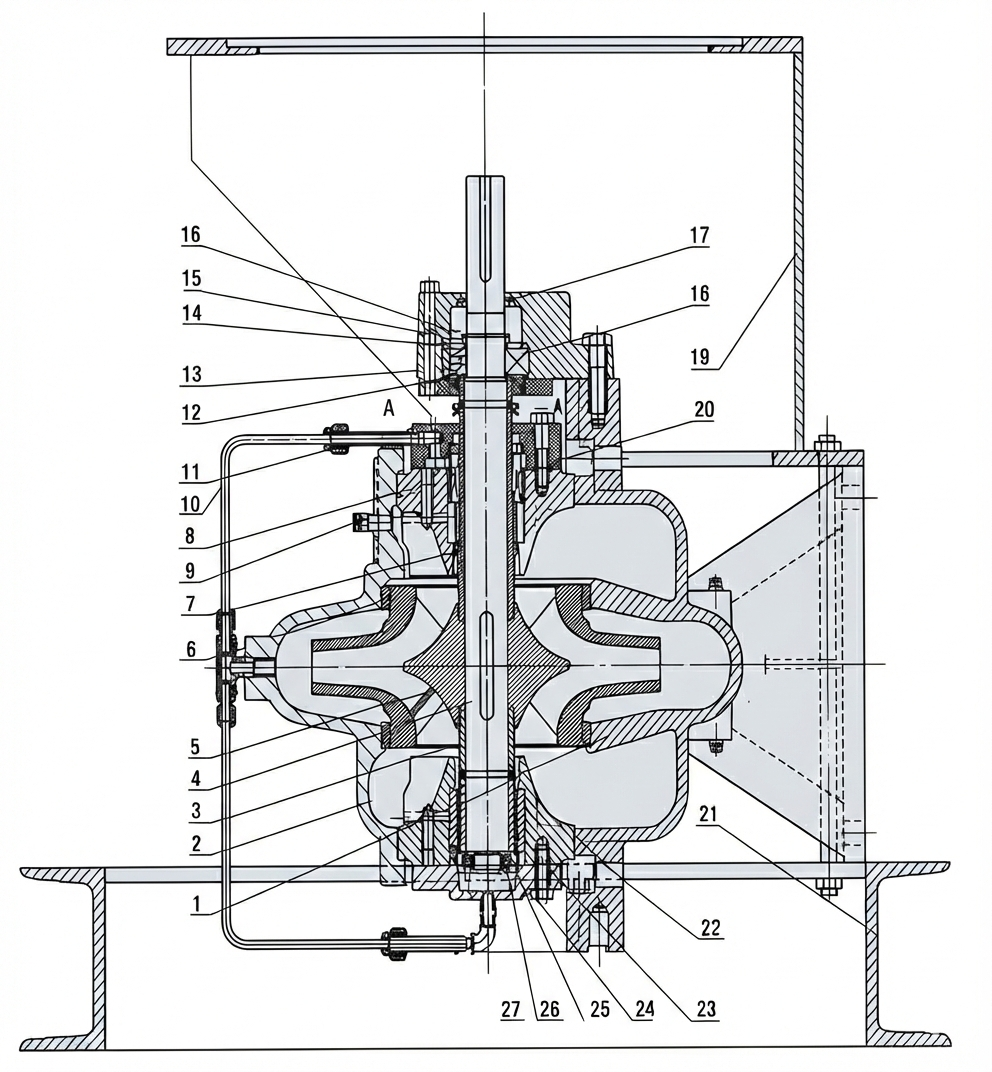

1 | Pump Casing | 9 | Seal Body | 17 | Skeleton Oil Seal | 25 | Stop Washer |

2 | Pump Cover | 10 | Flushing Pipe Assembly | 18 | Bearing | 26 | Lock Nut |

3 | Lower Shaft Sleeve A | 11 | Mechanical Seal Gland or Packing Gland | 19 | Motor Bracket | 27 | Guide Bearing |

4 | Shaft | 12 | Bearing Gland | 20 | Mechanical Seal or Packing Seal | ||

5 | Impeller | 13 | Bearing House | 21 | Base | ||

6 | Casing Seal Ring | 14 | Bearing Locating Ring | 22 | O-ring | ||

7 | Shaft Sleeve | 15 | Bearing Retaining Ring | 23 | Lower Shaft Sleeve B | ||

8 | Air Vent Valve | 16 | Circlip | 24 | Guide Bearing Gland |

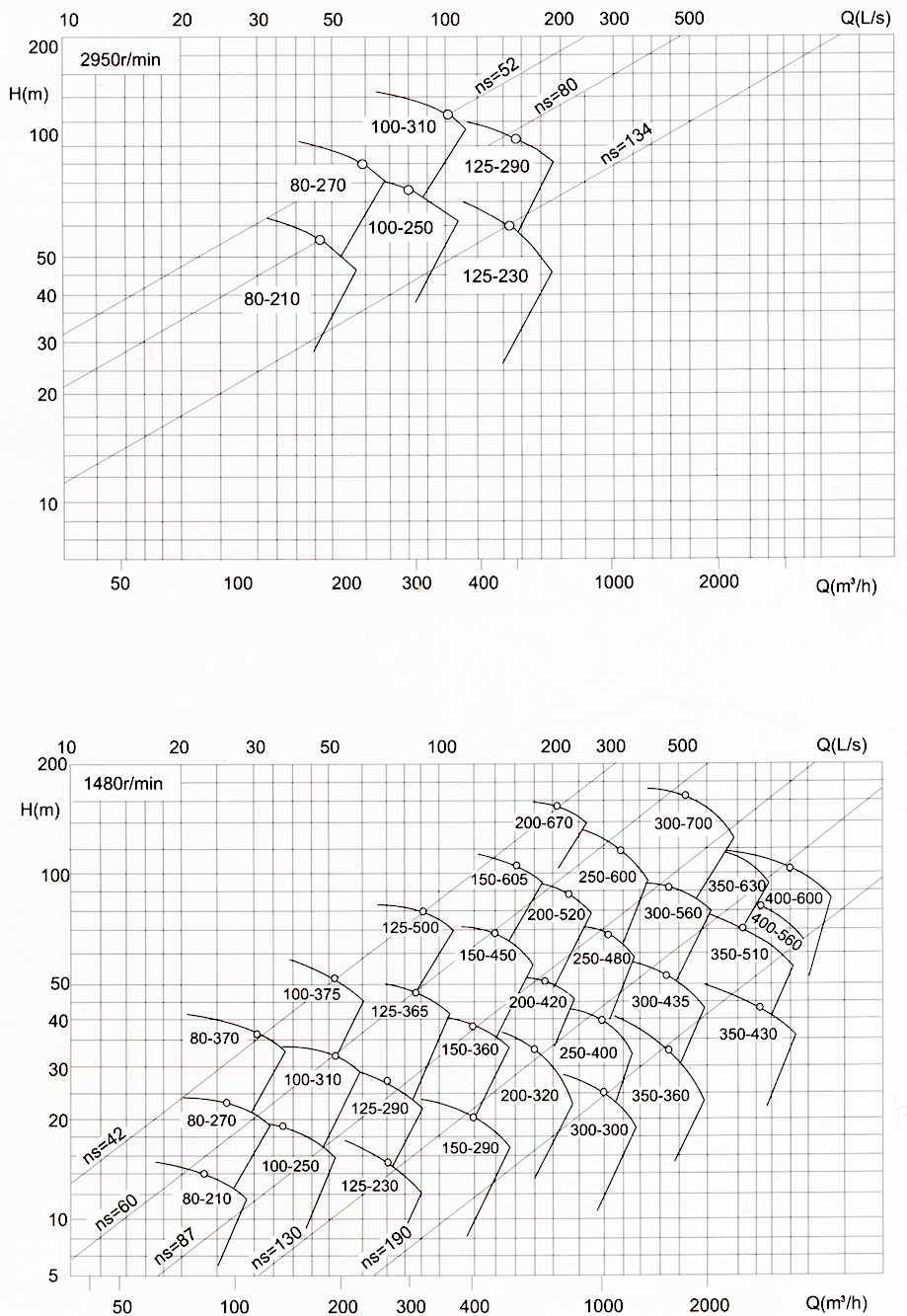

Quick Selection Chart

Technical Specifications Chart

NO. | Type | Capacity | Head | Speed | Motor power | Eff. | (NPSH)r | Weight | ||

m3/h | l/s | (m) | (r/min) | (kW) | (%) | (m) | (kg) | |||

1 | 80-210 | 22 | 6 | 17 | 1480 | 5.5 | 82 | 1.6 | 197 | |

83.5 | 23 | 13.8 | ||||||||

121 | 34 | 10 | ||||||||

2 | A | 22 | 6 | 14.8 | 4 | 81 | ||||

76 | 21 | 11.8 | ||||||||

108 | 30 | 8.7 | ||||||||

3 | B | 18 | 5 | 10.6 | 3 | 80.5 | ||||

72 | 20 | 9.8 | ||||||||

97 | 27 | 7.7 | ||||||||

4 | C | 14 | 4 | 9 | 3 | 78 | ||||

65 | 18 | 8.5 | ||||||||

83 | 23 | 7.9 | ||||||||

5 | 61 | 17 | 60.5 | 2950 | 37 | 82 | 4.5 | 197 | ||

165 | 46 | 55 | ||||||||

241 | 67 | 50 | ||||||||

6 | A | 58 | 16 | 58 | 30 | 81 | ||||

155 | 43 | 47.2 | ||||||||

220 | 61 | 34 | ||||||||

7 | B | 115 | 15 | 49.2 | 30 | 80.5 | ||||

144 | 39 | 38.5 | ||||||||

173 | 55 | 30.2 | ||||||||

8 | C | 50 | 14 | 42 | 22 | 77.8 | ||||

130 | 36 | 33.5 | ||||||||

169 | 47 | 27.5 | ||||||||

9 | 80-270 | 26 | 7.2 | 24.6 | 1480 | 11 | 78.5 | 2.3 | 206 | |

105 | 29 | 22.5 | ||||||||

137 | 38 | 18.1 | ||||||||

10 | A | 25 | 7 | 22 | 11 | 78 | ||||

97 | 27 | 19.2 | ||||||||

130 | 36 | 16 | ||||||||

11 | B | 22 | 6 | 19.5 | 7.5 | 78 | ||||

90 | 25 | 16.2 | ||||||||

115 | 32 | 13 | ||||||||

12 | C | 22 | 6 | 16.8 | 5.5 | 76 | ||||

79 | 22 | 13 | ||||||||

104 | 29 | 10.5 | ||||||||

13 | 80 | 22 | 107 | 2950 | 90 | 78 | 6.3 | 206 | ||

208.8 | 58 | 90 | ||||||||

280.8 | 78 | 77.5 | ||||||||

14 | A | 79 | 22 | 92.3 | 75 | 77 | ||||

191 | 53 | 77.5 | ||||||||

234 | 65 | 68.5 | ||||||||

15 | B | 76 | 21 | 77.5 | 55 | 76 | ||||

176 | 49 | 63.2 | ||||||||

220 | 61 | 55 | ||||||||

16 | C | 76 | 21 | 63.8 | 37 | 75 | ||||

155 | 43 | 50 | ||||||||

202 | 56 | 44.7 | ||||||||

17 | 80-370 | 29 | 8 | 43.5 | 1480 | 22 | 71.5 | 2.8 | 242 | |

115 | 32 | 38.9 | ||||||||

151 | 42 | 29.5 | ||||||||

18 | 25 | 7 | 37.7 | 15 | 70.5 | |||||

105 | 29 | 33.5 | ||||||||

133 | 37 | 25 | ||||||||

19 | 21.6 | 6 | 32 | 15 | 70 | |||||

97.2 | 27 | 27.7 | ||||||||

118.8 | 33 | 21.8 | ||||||||

20 | 22 | 6 | 25.8 | 11 | 67.5 | |||||

86 | 24 | 18.5 | ||||||||

100 | 28 | 13.1 | ||||||||

21 | 100-250 | 108 | 11 | 23.2 | 1480 | 11 | 82.5 | 3 | 245 | |

148 | 40 | 18.5 | ||||||||

187 | 59 | 13.1 | ||||||||

22 | A | 36 | 10 | 20 | 11 | 81 | ||||

133 | 37 | 15.7 | ||||||||

192 | 53 | 11.5 | ||||||||

23 | B | 36 | 10 | 17 | 7.5 | 79 | ||||

122 | 34 | 13.5 | ||||||||

172 | 48 | 10.2 | ||||||||

24 | C | 32 | 9 | 14.8 | 5.5 | 77.5 | ||||

115 | 32 | 11 | ||||||||

155 | 43 | 8.8 | ||||||||

25 | 148 | 41 | 90 | 2950 | 90 | 82.5 | 9.5 | 245 | ||

288 | 80 | 75 | ||||||||

374 | 104 | 82 | ||||||||

26 | A | 122 | 34 | 88 | 75 | 80.5 | ||||

266 | 74 | 63.2 | ||||||||

338 | 94 | 52.9 | ||||||||

27 | B | 68 | 19 | 67.8 | 55 | 79 | ||||

241 | 67 | 52 | ||||||||

324 | 90 | 43.5 | ||||||||

28 | C | 61 | 17 | 57.2 | 45 | 78 | ||||

223 | 62 | 44.8 | ||||||||

295 | 82 | 36 | ||||||||

29 | 100-310 | 47 | 13 | 38.1 | 1480 | 22 | 80 | 3.5 | 260 | |

187 | 52 | 31 | ||||||||

227 | 63 | 25.7 | ||||||||

30 | A | 44 | 12 | 33.4 | 18.5 | 79.6 | ||||

173 | 48 | 27 | ||||||||

205 | 57 | 22.8 | ||||||||

31 | B | 40 | 11 | 28 | 15 | 79.3 | ||||

158 | 44 | 23 | ||||||||

184 | 51 | 18.5 | ||||||||

32 | C | 36 | 10 | 23.2 | 11 | 79 | ||||

144 | 40 | 18.8 | ||||||||

165 | 46 | 16.4 | ||||||||

33 | 184 | 51 | 148.5 | 2950 | 200 | 80 | 11.5 | 260 | ||

367 | 102 | 123 | ||||||||

450 | 125 | 102 | ||||||||

34 | A | 140 | 39 | 130 | 132 | 79.6 | ||||

342 | 95 | 106 | ||||||||

410 | 114 | 89.5 | ||||||||

35 | B | 100 | 28 | 110 | 110 | 79.3 | ||||

313 | 87 | 90 | ||||||||

270 | 103 | 77.3 | ||||||||

36 | C | 119 | 33 | 93.5 | 90 | 79 | ||||

245 | 68 | 74 | ||||||||

324 | 90 | 63.8 | ||||||||

37 | 100-375 | 68 | 19 | 63.2 | 1480 | 45 | 73 | 2.9 | 310 | |

187 | 52 | 51.7 | ||||||||

241 | 67 | 39 | ||||||||

38 | A | 64.8 | 18 | 53 | 37 | 72 | ||||

169.2 | 47 | 44.5 | ||||||||

212.4 | 59 | 34 | ||||||||

39 | B | 61 | 17 | 46 | 30 | 71 | ||||

158 | 44 | 38 | ||||||||

190 | 53 | 31 | ||||||||

40 | C | 58 | 16 | 35.5 | 18.5 | 69 | ||||

142 | 39 | 30.3 | ||||||||

178 | 49 | 22.5 | ||||||||

41 | 125-230 | 100 | 28 | 20.2 | 1480 | 18.5 | 85.5 | 3 | 340 | |

274 | 76 | 15 | ||||||||

370 | 103 | 9.1 | ||||||||

42 | A | 94 | 26 | 18.5 | 15 | 84.5 | ||||

259 | 72 | 13.2 | ||||||||

331 | 92 | 8.5 | ||||||||

43 | B | 176 | 23 | 16 | 15 | 82.5 | ||||

230 | 65 | 10.2 | ||||||||

270 | 79 | 7.6 | ||||||||

44 | C | 162 | 22 | 13.2 | 11 | 77.5 | ||||

198 | 59 | 8.4 | ||||||||

241 | 67 | 6.5 | ||||||||

45 | 140 | 39 | 83.5 | 2950 | 132 | 85.5 | 9.5 | 340 | ||

532 | 148 | 60 | ||||||||

716 | 199 | 40 | ||||||||

46 | A | 122 | 34 | 73 | 110 | 84 | ||||

497 | 138 | 52 | ||||||||

652 | 181 | 36 | ||||||||

47 | B | 119 | 33 | 63.5 | 75 | 82 | ||||

454 | 126 | 43.5 | ||||||||

550 | 153 | 32 | ||||||||

48 | C | 104 | 29 | 63 | 75 | 77 | ||||

410 | 114 | 34 | ||||||||

460 | 128 | 30 | ||||||||

49 | 125-290 | 100 | 28 | 32.5 | 1480 | 30 | 84 | 3.1 | 390 | |

270 | 75 | 27 | ||||||||

374 | 104 | 21 | ||||||||

50 | A | 79 | 22 | 27.8 | 22 | 82 | ||||

245 | 68 | 21.8 | ||||||||

349 | 97 | 15.2 | ||||||||

51 | B | 75 | 21 | 23.5 | 18.5 | 80 | ||||

220 | 61 | 18 | ||||||||

310 | 86 | 12.5 | ||||||||

52 | C | 61 | 17 | 19 | 15 | 78 | ||||

194 | 54 | 14.2 | ||||||||

270 | 75 | 10.5 | ||||||||

53 | 382 | 106 | 120 | 2950 | 220 | 84 | 9.6 | 390 | ||

535 | 150 | 108 | ||||||||

640 | 178 | 93 | ||||||||

54 | A | 285 | 79 | 103.5 | 160 | 82 | ||||

483 | 134 | 88 | ||||||||

630 | 175 | 77.8 | ||||||||

55 | B | 190 | 53 | 92 | 132 | 80 | ||||

439 | 122 | 72 | ||||||||

605 | 168 | 60 | ||||||||

56 | C | 90 | 25 | 80 | 110 | 78 | ||||

389 | 108 | 57 | ||||||||

500 | 139 | 43.5 | ||||||||

57 | 125-365 | 126 | 35 | 53.1 | 1480 | 75 | 80 | 2.7 | 410 | |

310 | 86 | 47.2 | ||||||||

435 | 121 | 37.8 | ||||||||

58 | A | 105 | 29 | 45 | 45 | 79 | ||||

275 | 79 | 47 | ||||||||

396 | 110 | 37.5 | ||||||||

59 | B | 94 | 26 | 36.9 | 37 | 78 | ||||

255 | 71 | 31.5 | ||||||||

349 | 97 | 25 | ||||||||

60 | C | 86 | 24 | 27.9 | 30 | 76 | ||||

223 | 62 | 23.9 | ||||||||

396 | 110 | 18.8 | ||||||||

61 | 125-500 | 108 | 30 | 86 | 1480 | 110 | 80 | 3.5 | 450 | |

328 | 91 | 76 | ||||||||

382 | 106 | 71 | ||||||||

62 | A | 100 | 28 | 74.5 | 90 | 78.5 | ||||

306 | 85 | 66.5 | ||||||||

349 | 97 | 55 | ||||||||

63 | B | 79 | 22 | 64.8 | 75 | 77 | ||||

280 | 78 | 56.2 | ||||||||

300 | 83 | 51.5 | ||||||||

64 | C | 61 | 17 | 54.5 | 45 | 76 | ||||

252 | 70 | 44 | ||||||||

270 | 75 | 40.8 | ||||||||

65 | 150-290 | 158 | 44 | 27.3 | 1480 | 37 | 87 | 3.8 | 380 | |

443 | 123 | 21 | ||||||||

608 | 169 | 14.2 | ||||||||

66 | A | 151 | 42 | 25 | 30 | 86 | ||||

410 | 114 | 18.1 | ||||||||

550 | 153 | 12.5 | ||||||||

67 | B | 130 | 36 | 22.5 | 22 | 84 | ||||

367 | 102 | 15 | ||||||||

478 | 133 | 11.7 | ||||||||

68 | C | 112 | 34 | 17.4 | 18.5 | 77 | ||||

338 | 94 | 11.5 | ||||||||

396 | 110 | 9.7 | ||||||||

69 | 150-360 | 180 | 50 | 45.8 | 1480 | 75 | 85 | 4.1 | 420 | |

447 | 124 | 38 | ||||||||

590 | 164 | 31.2 | ||||||||

70 | A | 176 | 49 | 38.6 | 55 | 83 | ||||

403 | 112 | 31 | ||||||||

580 | 161 | 22.4 | ||||||||

71 | B | 310 | 45 | 33.1 | 37 | 81 | ||||

364 | 101 | 25 | ||||||||

496 | 138 | 18.1 | ||||||||

72 | C | 151 | 42 | 27.6 | 30 | 78 | ||||

324 | 90 | 20 | ||||||||

421 | 117 | 14.8 | ||||||||

73 | 150-450 | 202 | 56 | 76.1 | 1480 | 132 | 82 | 4 | 540 | |

515 | 143 | 66 | ||||||||

640 | 178 | 57.1 | ||||||||

74 | A | 190 | 53 | 64 | 110 | 81 | ||||

468 | 130 | 54.5 | ||||||||

601 | 167 | 45 | ||||||||

75 | B | 180 | 50 | 52.3 | 75 | 80 | ||||

418 | 116 | 43.5 | ||||||||

540 | 150 | 35 | ||||||||

76 | C | 176 | 49 | 42 | 55 | 78.5 | ||||

375 | 104 | 35 | ||||||||

468 | 130 | 27.8 | ||||||||

77 | 150-605 | 202 | 56 | 121 | 1480 | 250 | 80 | 4.5 | 650 | |

584 | 162 | 105 | ||||||||

730 | 203 | 92 | ||||||||

78 | A | 180 | 50 | 105 | 200 | 79 | ||||

536 | 149 | 88.5 | ||||||||

658 | 183 | 80 | ||||||||

79 | B | 169 | 47 | 90.8 | 160 | 78 | ||||

493 | 137 | 75 | ||||||||

620 | 172 | 68 | ||||||||

80 | C | 151 | 42 | 77.2 | 132 | 77 | ||||

450 | 125 | 61.5 | ||||||||

530 | 147 | 55.9 | ||||||||

81 | 200-320 | 248 | 69 | 40 | 1480 | 75 | 87.5 | 3.3 | 500 | |

695 | 193 | 30 | ||||||||

940 | 261 | 20 | ||||||||

82 | A | 241 | 67 | 34.8 | 75 | 86.5 | ||||

640 | 178 | 25.5 | ||||||||

846 | 235 | 17.3 | ||||||||

83 | B | 230 | 64 | 30.8 | 55 | 85 | ||||

587 | 163 | 21.2 | ||||||||

750 | 208 | 16.2 | ||||||||

84 | C | 220 | 61 | 25 | 37 | 79 | ||||

530 | 147 | 17 | ||||||||

608 | 169 | 15.2 | ||||||||

85 | 200-420 | 266 | 74 | 62.5 | 1480 | 132 | 86.5 | 4.2 | 560 | |

710 | 197 | 52 | ||||||||

990 | 275 | 40 | ||||||||

86 | A | 248 | 69 | 64 | 110 | 84.5 | ||||

642 | 178 | 42.6 | ||||||||

896 | 249 | 30.7 | ||||||||

87 | B | 238 | 66 | 46 | 90 | 83 | ||||

587 | 163 | 35.5 | ||||||||

781 | 217 | 24.8 | ||||||||

88 | C | 220 | 61 | 38.5 | 75 | 81 | ||||

525 | 146 | 28.5 | ||||||||

601 | 167 | 20.8 | ||||||||

89 | 200-520 | 475 | 132 | 102 | 1480 | 280 | 83 | 5 | 840 | |

817 | 227 | 91 | ||||||||

1080 | 300 | 77.5 | ||||||||

90 | A | 460 | 128 | 86 | 250 | 82 | ||||

748 | 208 | 76.6 | ||||||||

965 | 268 | 66.2 | ||||||||

91 | B | 440 | 122 | 71 | 200 | 80 | ||||

688 | 191 | 62.5 | ||||||||

905 | 251 | 52.3 | ||||||||

92 | C | 421 | 117 | 54.8 | 132 | 78.5 | ||||

630 | 175 | 47.5 | ||||||||

795 | 221 | 41.7 | ||||||||

93 | 200-670 | 280 | 78 | 167 | 1480 | 450 | 80 | 5 | 1200 | |

793 | 220 | 150 | ||||||||

936 | 260 | 139.8 | ||||||||

94 | A | 270 | 75 | 144 | 355 | 78.5 | ||||

730 | 203 | 126.8 | ||||||||

900 | 250 | 115 | ||||||||

95 | B | 260 | 72 | 124 | 315 | 77 | ||||

670 | 186 | 107 | ||||||||

864 | 240 | 93 | ||||||||

96 | C | 248 | 69 | 103 | 250 | 76 | ||||

637 | 177 | 88 | ||||||||

770 | 214 | 80 | ||||||||

97 | 250-400 | 400 | 111 | 50 | 1480 | 160 | 88 | 6 | 930 | |

1052 | 292 | 39 | ||||||||

1480 | 403 | 28 | ||||||||

98 | A | 382 | 106 | 44.6 | 132 | 86 | ||||

968 | 269 | 33 | ||||||||

1310 | 364 | 24 | ||||||||

99 | B | 378 | 105 | 38.1 | 110 | 83 | ||||

914 | 254 | 27.1 | ||||||||

1159 | 322 | 20.2 | ||||||||

100 | C | 350 | 97 | 31.8 | 75 | 77.5 | ||||

842 | 234 | 20.1 | ||||||||

990 | 275 | 16.1 | ||||||||

101 | 250-480 | 421 | 117 | 82.6 | 1480 | 280 | 87 | 7.7 | 1200 | |

1175 | 326 | 66 | ||||||||

1610 | 447 | 50 | ||||||||

102 | A | 400 | 111 | 69 | 220 | 85 | ||||

1073 | 298 | 55 | ||||||||

1480 | 403 | 41.5 | ||||||||

103 | B | 370 | 103 | 58 | 200 | 83 | ||||

975 | 271 | 45.5 | ||||||||

1249 | 347 | 36 | ||||||||

104 | C | 331 | 92 | 49.4 | 160 | 80 | ||||

904 | 251 | 37.5 | ||||||||

1090 | 303 | 31.2 | ||||||||

105 | 250-600 | 800 | 222 | 131 | 1480 | 560 | 84 | 7.8 | 1310 | |

1243 | 345 | 116 | ||||||||

1642 | 456 | 97.8 | ||||||||

106 | A | 750 | 208 | 115.1 | 450 | 83.5 | ||||

1155 | 321 | 99.8 | ||||||||

1598 | 444 | 79.2 | ||||||||

107 | B | 698 | 194 | 95.2 | 315 | 83 | ||||

1051 | 292 | 83 | ||||||||

1480 | 411 | 63 | ||||||||

108 | C | 652 | 181 | 77.8 | 250 | 82.5 | ||||

968 | 269 | 66.2 | ||||||||

1360 | 378 | 50 | ||||||||

109 | 300-300 | 500 | 139 | 36 | 1480 | 110 | 86 | 4.6 | 900 | |

1098 | 305 | 24.5 | ||||||||

1476 | 410 | 16.9 | ||||||||

110 | A | 478 | 133 | 31.9 | 90 | 84.5 | ||||

1018 | 283 | 20 | ||||||||

1425 | 396 | 12.1 | ||||||||

111 | B | 460 | 128 | 26.4 | 75 | 82 | ||||

968 | 269 | 15.6 | ||||||||

1288 | 358 | 9.1 | ||||||||

112 | C | 439 | 122 | 22.3 | 45 | 80 | ||||

922 | 256 | 11.4 | ||||||||

1170 | 325 | 7.5 | ||||||||

113 | 300-435 | 698 | 194 | 67.7 | 1480 | 315 | 88 | 5.2 | 1200 | |

1680 | 466 | 53 | ||||||||

2379 | 661 | 37 | ||||||||

114 | A | 658 | 183 | 59.3 | 280 | 86.5 | ||||

1576 | 438 | 45 | ||||||||

2098 | 583 | 32.2 | ||||||||

115 | B | 619 | 172 | 50 | 200 | 84 | ||||

1476 | 410 | 36.5 | ||||||||

1800 | 500 | 27.5 | ||||||||

116 | C | 601 | 167 | 40.8 | 160 | 79 | ||||

1360 | 378 | 27.5 | ||||||||

1480 | 403 | 24.3 | ||||||||

117 | 300-560 | 698 | 194 | 115.2 | 1480 | 630 | 86 | 4.2 | 1650 | |

1750 | 486 | 94 | ||||||||

2350.8 | 653 | 75.9 | ||||||||

118 | A | 680 | 189 | 92 | 450 | 85.5 | ||||

1645 | 457 | 76 | ||||||||

2170 | 603 | 61.4 | ||||||||

119 | B | 651 | 181 | 77.3 | 355 | 85 | ||||

1573 | 437 | 62 | ||||||||

2131 | 592 | 46.8 | ||||||||

120 | C | 619 | 172 | 65 | 280 | 83.5 | ||||

1515 | 421 | 50 | ||||||||

1980 | 550 | 37.5 | ||||||||

121 | 300-700 | 900 | 250 | 183 | 1480 | 1120 | 85 | 3.5 | 1850 | |

1836 | 510 | 160 | ||||||||

2100 | 583 | 150.7 | ||||||||

122 | A | 961 | 267 | 159.8 | 900 | 84.6 | ||||

1735 | 482 | 136 | ||||||||

2030 | 564 | 126 | ||||||||

123 | B | 800 | 222 | 135 | 630 | 84.3 | ||||

1624 | 451 | 112 | ||||||||

1879 | 522 | 104 | ||||||||

124 | C | 698 | 194 | 110.7 | 560 | 84 | ||||

1537 | 427 | 91 | ||||||||

1598 | 444 | 77.3 | ||||||||

125 | 350-360 | 601 | 167 | 45.3 | 1480 | 200 | 86.5 | 6.2 | 1210 | |

1733 | 481 | 32 | ||||||||

2278 | 633 | 20.6 | ||||||||

126 | A | 580 | 161 | 40 | 160 | 85 | ||||

1692 | 470 | 26.5 | ||||||||

2160 | 600 | 17 | ||||||||

127 | B | 561 | 156 | 33.8 | 132 | 83 | ||||

1642 | 456 | 21 | ||||||||

2084 | 578 | 12.7 | ||||||||

128 | C | 540 | 150 | 27.9 | 110 | 80.5 | ||||

1602 | 445 | 15 | ||||||||

1900 | 528 | 8.9 | ||||||||

129 | 350-430 | 1000 | 278 | 59 | 1480 | 450 | 87.5 | 8.5 | 1630 | |

2745 | 763 | 43.5 | ||||||||

3500 | 972 | 31 | ||||||||

130 | A | 950 | 264 | 50.5 | 355 | 85.5 | ||||

2635 | 732 | 35 | ||||||||

3448 | 958 | 22.2 | ||||||||

131 | B | 900 | 250 | 43 | 280 | 84 | ||||

2563 | 712 | 27.5 | ||||||||

3250 | 903 | 18.3 | ||||||||

132 | C | 890 | 247 | 36 | 220 | 81 | ||||

2484 | 690 | 21.5 | ||||||||

3200 | 889 | 13 | ||||||||

133 | 350-510 | 1350 | 375 | 94 | 1480 | 630 | 88.5 | 6.7 | 1500 | |

2610 | 725 | 70 | ||||||||

3700 | 1028 | 48.2 | ||||||||

134 | A | 1980 | 550 | 67.5 | 560 | 87 | ||||

2434 | 676 | 60 | ||||||||

2880 | 800 | 51 | ||||||||

135 | B | 1872 | 520 | 56 | 400 | 86 | ||||

2304 | 640 | 49 | ||||||||

2628 | 730 | 42 | ||||||||

136 | C | 1800 | 500 | 42.8 | 315 | 79 | ||||

2088 | 580 | 37.5 | ||||||||

2376 | 660 | 32.5 | ||||||||

Click here to view the specifications for Split-case Pump models KLS350-630 to KLS800-990.

Installation and Maintenance Guide

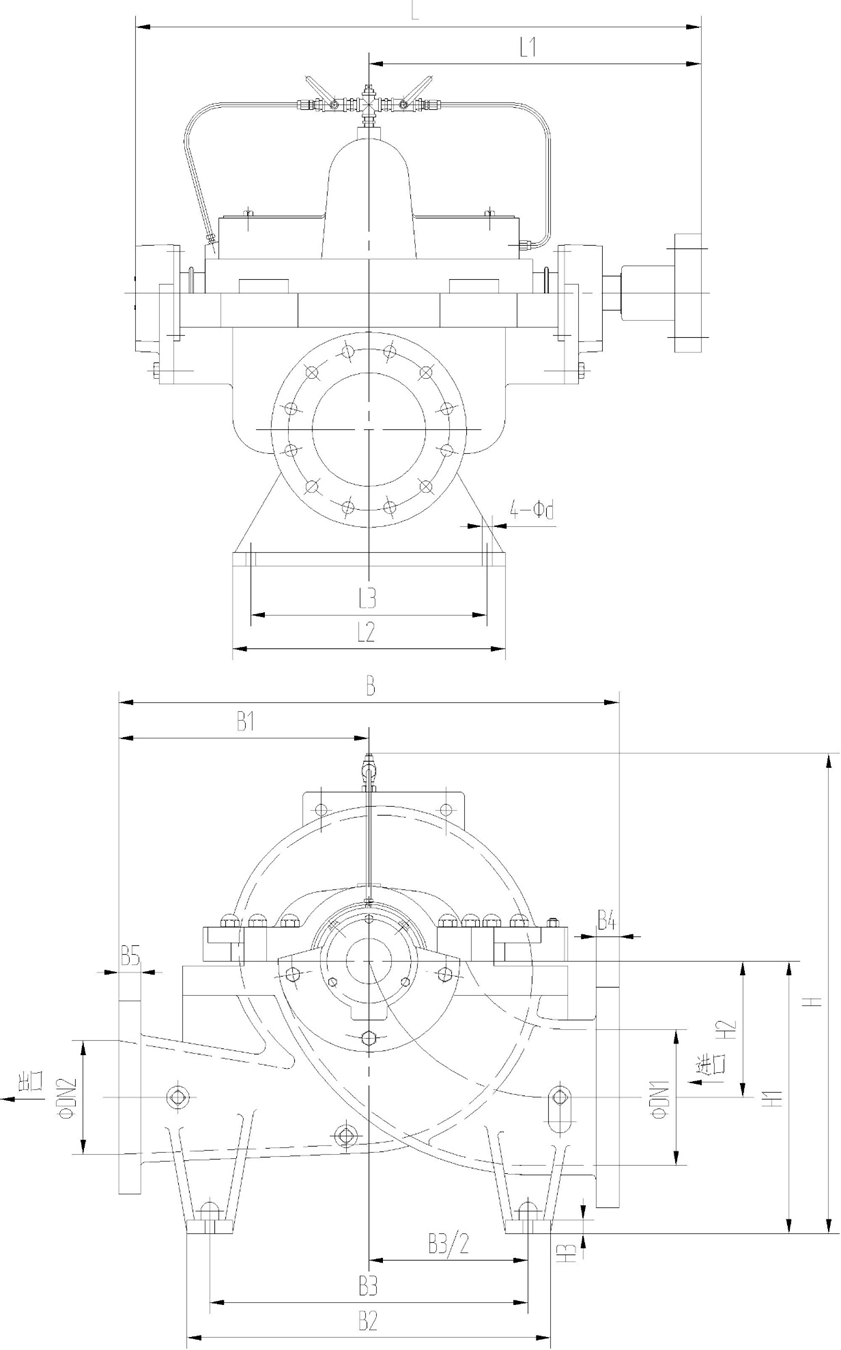

Outline Dimensions Table for Small KLS Pumps (Unit: mm)

Type | L | L1 | L2 | L3 | B | B1 | B2 | B3 | B4 | B5 | H | H1 | H2 | H3 | 4-φd |

80-210 | 702 | 402 | 320 | 270 | 600 | 300 | 410 | 340 | 26 | 26 | 590 | 315 | 140 | 30 | 4-φ18 |

80-270 | 605 | ||||||||||||||

80-370 | 660 | 330 | 645 | ||||||||||||

100-250 | 470 | 400 | 30 | 26 | 655 | 355 | 170 | ||||||||

100-310 | 685 | ||||||||||||||

100-375 | 370 | 370 | 26 | 24 | 715 | ||||||||||

125-230 | 863 | 498 | 390 | 340 | 740 | 370 | 530 | 450 | 30 | 26 | 725 | 400 | 200 | 30 | 4-φ18 |

125-290 | 740 | ||||||||||||||

125-365 | 765 | ||||||||||||||

125-500 | 900 | 450 | 630 | 560 | 805 | ||||||||||

150-290 | 863 | 498 | 400 | 340 | 800 | 400 | 530 | 450 | 30 | 30 | 745 | 400 | 200 | 30 | 4-φ18 |

150-360 | 390 | 340 | 770 | 35 | |||||||||||

150-450 | 976 | 555 | 480 | 430 | 900 | 450 | 630 | 560 | 715 | 4-φ22 | |||||

150-605 | 1100 | 500 | 770 | 700 | 970 | 500 | 300 | ||||||||

200-320 | 976 | 555 | 480 | 430 | 900 | 450 | 630 | 560 | 32 | 30 | 880 | 500 | 240 | 35 | 4-φ22 |

200-420 | 1000 | 500 | 910 | ||||||||||||

200-520 | 1088 | 624 | 1100 | 500 | 770 | 700 | 1025 | 560 | 300 | ||||||

200-670 | 400 | 1200 | 550 | 800 | 700 | 1140 | 600 | 350 | |||||||

250-400 | 1088 | 624 | 480 | 400 | 1000 | 500 | 800 | 700 | 36 | 32 | 1045 | 600 | 300 | 42 | 4-φ22 |

250-480 | 1196 | 683 | 600 | 520 | 1100 | 550 | 1067 | ||||||||

250-600 | 1200 | 550 | 1160 | 630 | 350 | ||||||||||

300-300 | 1088 | 624 | 480 | 400 | 1050 | 500 | 800 | 700 | 40 | 36 | 1085 | 630 | 300 | 42 | 4-φ22 |

300-435 | 1196 | 683 | 600 | 520 | 1200 | 550 | 44 | 36 | 1152 | 670 | 350 | ||||

300-560 | 1383 | 788 | 1350 | 650 | 1050 | 950 | 48 | 40 | 1235 | 710 | 350 | ||||

300-700 | 1400 | 650 | 1345 | 750 | 400 | ||||||||||

350-360 | 1196 | 683 | 600 | 520 | 1200 | 550 | 800 | 700 | 44 | 40 | 1190 | 670 | 350 | 42 | 4-φ22 |

350-430 | 1383 | 788 | 1400 | 650 | 1050 | 950 | 1310 | 750 | 400 | ||||||

350-510 | 1350 | 650 | 1270 |

Applications

The KLS Series is engineered for high-flow water transfer across diverse sectors:

Municipal: Urban water supply, boosting stations, and flood control.

HVAC: Cooling tower circulation and district heating systems.

Industrial: Process water for power plants, steel mills, and fire-fighting.

Agriculture: Large-scale irrigation and drainage projects.

FAQ

Q1: What are the maintenance benefits of the split-case design?

A: The axially split casing allows for easy access to internal components (impeller, bearings, seals) without disturbing the piping, significantly reducing downtime and maintenance costs.

Q2: Can this pump be installed vertically?

A: Yes. While horizontal is standard, the KLS series supports both horizontal and vertical configurations to suit your pump room layout.

Q3: What materials are available?

A: Beyond standard cast iron, we offer ductile iron, stainless steel (304/316), and bronze to handle corrosive or abrasive fluids.

Q4: Is it suitable for wastewater?

A: It is designed for clean water or liquids with similar properties. For fluids with minor solids, please contact us to customize the seal and material selection.

Categories

Contact Us

- +86-15031155425

- sales@kendapump.com

- +86-15031155425