Heavy Duty Rubber Lined Slurry Pump | KH & KHR Series | Kenda Pump

Anti-Abrasive Rubber Lined Slurry Pump for Mining & Chemical Processing

100% compatible with Warman AH & AHR series slurry pumps

SPECIFICATIONS:

-Discharge diameters 1” to 18” (25mm to 450mm)

-Capacity: up to 2520 m³/h

-Head: up to 55m

-Speed: 300-3400r/min

-Materials: Cast iron, Ductile iron, High chrome alloy, Natural rubber etc

Kenda KH & KHR Series Slurry Pumps Key Features | Wear-resistant and Corrosion-resistant Industrial Conveying Solutions

Rubber Lined Slurry Pumps Technical Advantages

1. Superior Wear Resistance for Fine Particles

Unlike metal liners, high-quality natural rubber possesses unique elastomeric properties. When pumping slurries containing fine particles (typically smaller than 6.5mm), the rubber surface deforms to absorb the kinetic energy of the impact and then bounces the particles off. This "softness" allows rubber liners to outlast high-chrome alloys by 2–3 times in specific abrasive applications.

2. Excellent Corrosion and Chemical Resistance

Metal liners are susceptible to chemical attack in acidic or alkaline environments. Kenda’s rubber linings (such as EPDM or synthetic blends) are engineered to withstand a wide range of chemical media with PH levels from 3 to 12. This makes our pumps the ideal choice for chemical processing, phosphate mining, and Flue Gas Desulfurization (FGD) applications.

3. Comparison: Rubber Lined vs. High Chrome Alloy

Feature | Rubber Lined (KH/KHR Series) | High Chrome Alloy (A05/A49) |

Best Particle Size | Fine Particles (< 6.5mm) | Large, Sharp, or Coarse Solids |

Corrosion Resistance | Excellent (Wide PH Range) | Limited (Weak Acids Only) |

Component Weight | Lightweight (Easy Maintenance) | Heavy (Requires Lifting Gear) |

Noise & Vibration | Low (Dampens Operation Noise) | Higher (Metal-on-Metal Impact) |

Cost Efficiency | Lower Spare Parts Cost | Higher Initial Investment |

4. Tailored Material Options for Diverse Conditions

We provide a variety of specialized rubber compounds to match your specific working environment:

Natural Rubber (NR08/NR26/NR55): The gold standard for high abrasion resistance and fine particle handling.

Butyl / EPDM: Specifically designed for high-temperature slurries and aggressive chemical environments.

Nitrile (NBR): Engineered for slurries containing oils, fats, or hydrocarbon solvents.

5. Lower Total Cost of Ownership (TCO)

Rubber-lined components are significantly lighter than their metal counterparts, meaning they do not require heavy lifting equipment during replacement. This reduces maintenance downtime and labor costs. Combined with a longer service life in corrosive environments, Kenda rubber pumps significantly lower your annual operational expenses.

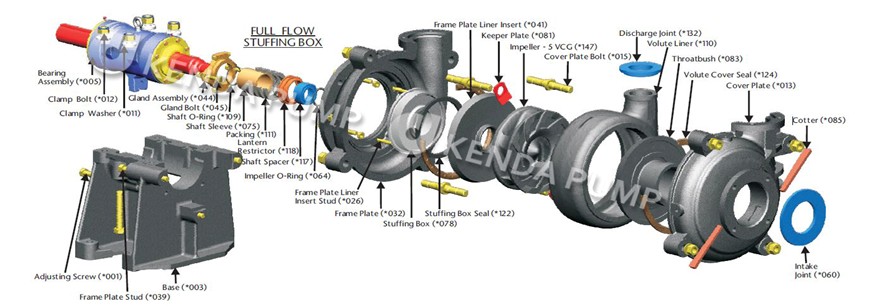

Kenda KH & KHR Slurry Pump Structure

Features

Pump- Cantilever, horizontal centrifugal slurry pump.

Wet parts-Impellers, volutes, liners are made of high chrome alloy or rubber or polyurethane, anti-abrasive, wear resistant and corrosion resistance.

Bearing assembly- Tubular structure bearing assembly, design of high capacity bearing. Grease lubrication, oil lubrication helps to adapt to different operating conditions.

Shaft seal- Sealed by packing or centrifugal.

Pump exit position- Based on 450 interval, rotating eight different angles of installation.

Kenda KH/KHR Series Slurry Pump Technical Specifications Chart

Model | Max. Motor Power (kW) | Material | Clear Water Performance | Impel. Dia. (mm) | |||||

Liner | Impeller | Capacity Q (m³/h) | Head H(m) | Pump Speed n(r/min) | Max. Eff. η% | NPSH (m) | |||

KH-1B | 15 | M | M | 12.6-28.8 | 6-68 | 1200-3800 | 40 | 2-4 | 152 |

KHR-1B | 15 | RU | RU | 10.8-25.2 | 7-52 | 1400-3400 | 35 | 2-4 | 152 |

KHH-1C | 30 | M | M | 16.2-34.2 | 25-92 | 1400-2200 | 20 | 2-5.5 | 330 |

KH-1.5B | 15 | M | M | 32.4-72 | 6-58 | 1200-3200 | 45 | 3.5-8 | 184 |

KHR-1.5B | 15 | RU | RU | 25.2-54 | 5.5-41 | 1000-2600 | 50 | 2.5-5 | 178 |

KH-2C | 30 | M | M | 39.6-86.4 | 12-64 | 1300-2700 | 55 | 4-6 | 214 |

KHR-2C | 30 | RU | RU | 36-75.6 | 13-46 | 1300-2300 | 60 | 2-4 | 213 |

KHH-2D | 60 | M | M | 68.4-136.8 | 25-87 | 850-1400 | 47 | 3-7.5 | 457 |

KH-3C | 30 | M | M | 86.4-198 | 9-52 | 1000-2200 | 71 | 4-6 | 245 |

KH-3D | 60 | M | M | 86.4-198 | 9-52 | 1000-2200 | 71 | 4-6 | 245 |

KHR-3C | 30 | RU | RU | 79.2-180 | 5-34.5 | 800-1800 | 59 | 3-5 | 245 |

KHR-3D | 60 | RU | RU | 79.2-180 | 5-34.5 | 800-1800 | 59 | 3-5 | 245 |

KHH-3E | 120 | M | M | 126-252 | 12-97 | 600-1400 | 50 | 2-5 | 508 |

KH-4D | 60 | M | M | 162-360 | 12-56 | 800-1550 | 65 | 5-8 | 365 |

KH-4E | 120 | M | M | 162-360 | 12-56 | 800-1550 | 65 | 5-8 | 365 |

KHR-4D | 60 | RU | RU | 144-324 | 12-45 | 800-1350 | 65 | 3-5 | 365 |

KHR-4E | 120 | RU | RU | 144-324 | 12-45 | 800-1350 | 65 | 3-5 | 365 |

KHH-4F | 260 | M | M | 324-720 | 30-118 | 600-1000 | 64 | 3-8 | 711 |

KHH-6S | 560 | M | M | 468-1008 | 20-94 | 500-1000 | 65 | 4-12 | 711 |

KH-6E | 120 | M | M | 360-828 | 10-61 | 500-1140 | 72 | 2-9 | 510 |

KH-6R | 300 | M | M | 360-828 | 10-61 | 500-1140 | 72 | 2-9 | 510 |

KHR-6E | 120 | RU | RU | 32-720 | 7-49 | 400-1000 | 65 | 5-10 | 510 |

KHR-6R | 300 | RU | RU | 32-720 | 7-49 | 400-1000 | 65 | 5-10 | 510 |

KH-8ST | 560 | M | M | 612-1368 | 11-61 | 400-850 | 71 | 4-10 | 686 |

KHR-8ST | 560 | RU | RU | 540-1188 | 12-50 | 400-750 | 75 | 4-12 | 686 |

KM-8E | 120 | M | M | 540-1440 | 14-60 | 600-1000 | 73 | 4-10 | 549 |

KM-8R | 300 | M | M | 540-1440 | 14-60 | 600-1000 | 73 | 4-10 | 549 |

KH-10ST | 560 | M | M | 936-1980 | 7-68 | 330-800 | 82 | 6 | 762 |

KHR-10ST | 560 | RU | RU | 720-1620 | 7-45 | 300-650 | 80 | 2.5-7.5 | 762 |

KH-12ST | 560 | M | M | 1260-2772 | 13-63 | 300-600 | 77 | 3-10 | 965 |

KHR-12ST | 560 | RU | RU | 1152-2520 | 13-44 | 300-500 | 79 | 3-8 | 965 |

KH-14TU | 1200 | M | M | 1368-3060 | 11-63 | 250-550 | 79 | 4-10 | 1067 |

KH-16TU | 1200 | M | M | 2160-5054 | 8-66 | 200-500 | 80 | 4.5-9 | 1245 |

KH-18TU | 1200 | M | M | 2520-5400 | 13-57 | 200-400 | 85 | 5-10 | 1370 |

Kenda KH/KHR Series Slurry Pump Material Options Chart

Slurry Pump Parts | Material | Specification | HRC | Application | Material Code |

Volute Liner, Impeller | Hard Metal | 23%-30% chrome white iron | ≥56 | Used for higher wear conditions with PH between 5 to 12 | A05 |

14%-18% chrome white iron | ≥59 | Used for higher wear conditions | A07 | ||

27%-29% chrome white iron | 43 | Used for lower PH conditions especially for FGD. Its also can be used for low-sour conditions and desulfuration with PH no less than 4. | A49 | ||

Rubber | Standard Impeller Rubber | R08 | |||

Standard Liner Rubber | R26 | ||||

Natural rubber (soft) | R33 | ||||

Natural rubber | R55 | ||||

Hypalon | S31 | ||||

PU | Polyurethane | U01 | |||

Expeller, Expeller Ring | Metal | 23%-30% chrome white iron | ≥56 | Used for higher wear conditions with PH between 5 to 12 | A05 |

Grey iron | G01 | ||||

Stuffing Box | Metal | 23%-30% chrome white iron | ≥56 | Used for higher wear conditions with PH between 5 to 12 | A05 |

Grey iron | G01 | ||||

Frame Plate, Cover Plate, Bearing House, Base | Metal | Grey iron | G01 | ||

Ductile iron | D21 | ||||

Shaft | Metal | Carbon Steel | E05 | ||

Shaft Sleeve, Lantern Ring, Resctrictor Neck Ring, Gland Bolt | Stainless Steel | 4Cr13 | C21 | ||

304 SS | C22 | ||||

316 SS | C23 | ||||

Joint Rings, Seals | Rubber | Butyl rubber | S21 | ||

EPDM rubber | S01 | ||||

Nitrile | S10 | ||||

Hypalon | S31 | ||||

Neoprene | S44, S42 | ||||

Viton | S50 |

Rubber Lined Slurry Pump Applications:

• Mining | • Mineral processing | • Coal prep | • Cyclone feeds |

• Tunnel | • Chemical slurries | • Tailings | • Mill grinding |

• Ash handing | • Paper and Pulp | • Waste sludge | • Coarse sand |

• Lime mud | • Phosphoric acid | • Dredging | • Construction |

• Alumina Industry | • Power Plant | • Potash Fertilizer Plant | • Other industries |

FAQ: Maintaining and Operating Rubber Lined Slurry Pumps

1.How to maintain a rubber lined slurry pump?

Proper maintenance is crucial to maximize the lifespan of the rubber components and prevent unexpected downtime.

Prevent Dry Running: This is the most critical rule. Rubber liners rely on the slurry for cooling. Dry running causes friction heat that can char or debond the rubber from the metal casing within minutes.

Check Impeller Clearance: Regularly adjust the clearance between the impeller and the throatbush. Maintaining the correct gap ensures hydraulic efficiency and prevents localized turbulence that can cause "gouging" in the rubber.

Monitor Seal Integrity: Whether using packing seals, expeller seals, or mechanical seals, ensure they are properly lubricated and cooled. Leakage can lead to shaft damage or slurry entering the bearing assembly.

Liner Inspection: Periodically check for signs of tearing, debonding, or bubbling. If a tear is caught early, it may prevent the slurry from reaching and eroding the outer metal casing.

Bearing Lubrication: Follow a strict lubrication schedule using the manufacturer-recommended grease to ensure smooth operation and low vibration.

2. What is the maximum particle size for rubber lined pumps?

Rubber liners are designed for fine-particle slurries where the primary wear mechanism is sliding abrasion.

General Limit: Most rubber liners are optimized for particles up to 6.5 mm (1/4 inch).

Shape Matters: While rubber can handle slightly larger rounded particles (like fine sand), sharp or angular solids (like crushed rock) can cut or tear the rubber surface upon impact.

The Velocity Factor: If your application involves high-head or high-speed operation, the particle size limit should be more conservative to prevent "impingement wear." For slurries containing large or sharp rocks, we recommend switching to Kenda’s high-chrome alloy liners.

3. Can these pumps handle acidic slurries?

Yes, absolutely. This is one of the primary advantages of rubber-lined pumps over metal ones.

Corrosion Resistance: Unlike high-chrome alloys, which can corrode quickly in low PH environments, rubber is naturally inert to many chemicals.

PH Range: Standard natural rubber liners are excellent for a PH range of 3 to 12.

Specialized Compounds: For highly aggressive acidic environments or temperatures exceeding 60°C, Kenda offers specialized synthetic liners:

EPDM/Butyl: Ideal for concentrated acids and high-temperature chemical processing.

Nitrile: Best for slurries containing oil or hydrocarbon traces that would cause natural rubber to swell and fail.

Expert Consultation: We recommend providing a full chemical analysis of your slurry so our engineers can match the exact rubber compound to your PH and temperature requirements.

Case Studies

Case Study 1: Copper Tailings (Chile)

Challenge: Metal liners failed every 3 months due to fine particle abrasion (<2mm).

Solution: Kenda KHR Series with NR08 Natural Rubber.

Result: Service life tripled to 9 months; maintenance costs dropped by 40%.

Case Study 2: Power Plant FGD System

Challenge: Acidic limestone slurry (pH 4.5) caused rapid corrosion and leaks in metal pumps.

Solution: Kenda Custom EPDM-lined Slurry Pumps.

Result: 14+ months of leak-free operation in corrosive, high-temp conditions.

Looking for durable Rubber Lined Slurry Pump? Kenda's rubber lined slurry pumps offer superior abrasion resistance for mining and mineral processing. 100% Interchangeable with Warman AH。Request a quick quote today!

Categories

Contact Us

- +86-15031155425

- sales@kendapump.com

- +86-15031155425